75G Impact Label

Product Details:

- Processing Type Standard

- Condition New

- Click to View more

X

75G Impact Label Price And Quantity

- 100-500 , , Piece

75G Impact Label Product Specifications

- Standard

- New

75G Impact Label Trade Information

- Keelung

- 500000 , , Piece Per Month

- 1 Week

- Yes

- Free samples are available

- Please Contact us for more details.

- All India

- SGS

Product Description

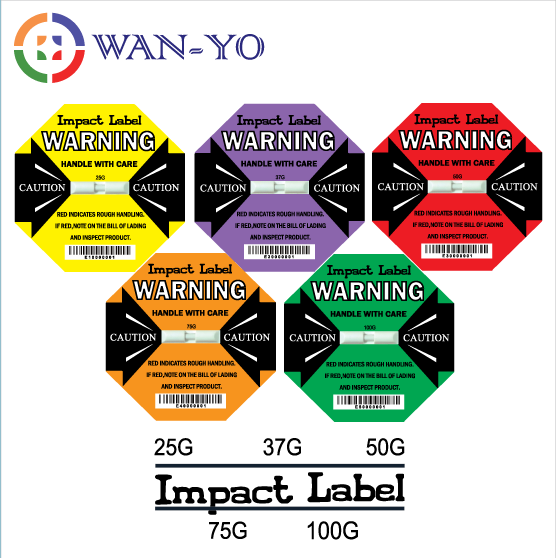

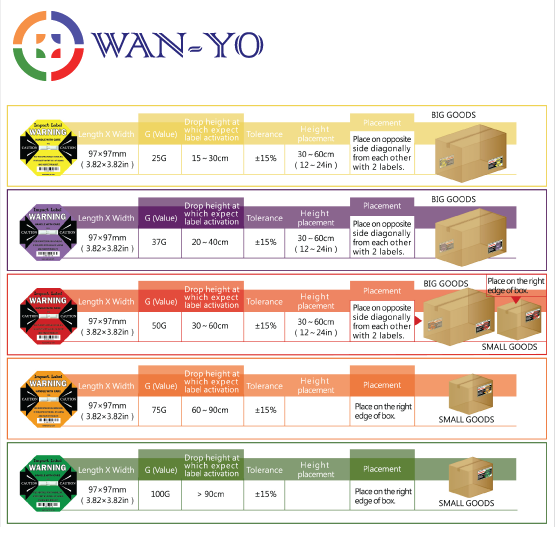

The purpose of the 75G Impact Label is to identify shocks that occur during transit. It is fastened to the exterior of the box to detect vibrations, impacts, and product falls. This indicator window changes from red to white and cannot be reset if it crosses the 75 G threshold. Wafers, motherboards, connectors, and other devices are among the items that use this 75G Impact Label. Its strong adhesiveness enables it to remain on the surface for longer.

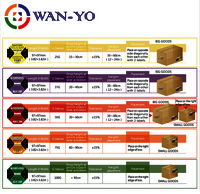

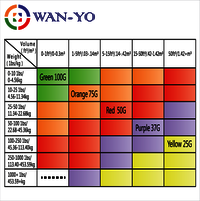

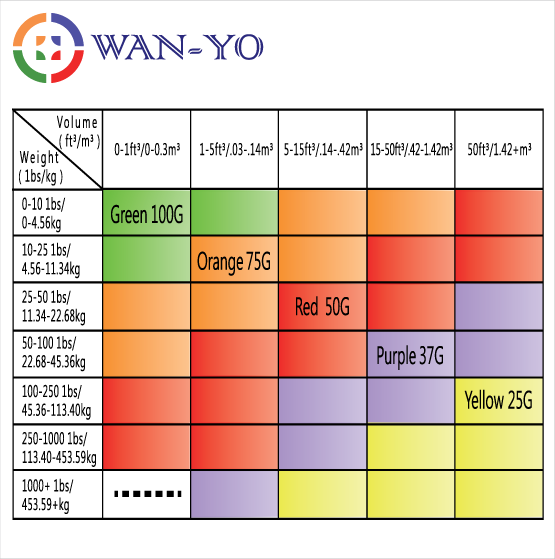

| Product Name | Impact Label |

| Models | L-65, L-55, L-47, L-35, L-30 |

| Dimension | 97mm*97mm (3.82 in 3.82in) |

| Sensitivity | 25G, 37G, 50G, 75G, 100G |

| Tolerance | + 15% |

| Reaction Time | 0.5 - 50 ms |

| Operating Temperature | -25oC to 80oC (-13oF to 176oF) |

| Installation | Back Adhesive |

| Shelf Life | 2 Years |

Advanced Impact Detection for Safer Shipments

The 75G Impact Label is engineered to enhance logistics safety by indicating mishandling during transportation. When exposed to rough handling beyond its set threshold, the indicator turns red, serving as a visual alert to potential shipment damage. This facilitates timely inspection and documentation while fostering greater accountability throughout the supply chain.

Customizable and Easy to Install

Tailored to meet diverse packaging requirements, the 75G Impact Label can be produced in any size specified by the buyer. The installation process is intuitive, requiring no specialized tools, making it seamlessly adaptable to varied workflows for manufacturers, exporters, and distributors alike.

FAQs of 75G Impact Label:

Q: How does the 75G Impact Label indicate rough handling during shipment?

A: The 75G Impact Label uses an advanced mechanism that changes its color from transparent to red when it experiences an impact above the preset threshold, providing a clear and immediate indication of rough handling during transit.Q: What steps should I take if the impact label turns red upon delivery?

A: If the label appears red, immediately note this on the bill of lading and inspect the products for possible damage before accepting the delivery. This documentation helps during any claims or dispute resolution processes.Q: When should the 75G Impact Label be applied to packages?

A: It is recommended to apply the label to packages right before shipping or dispatch, ensuring that it accurately reflects any impacts incurred during transportation from the point of origin.Q: Where can I order the 75G Impact Label with customized size options?

A: You can order the impact label directly from our facilities in Taiwan, as we operate as a manufacturer, distributor, exporter, supplier, and trader. We customize sizes as per buyers specific requirements.Q: What is the installation process for the label, and is it difficult to attach?

A: Installing the 75G Impact Label is quite user-friendly. Simply affix the label to a clean, flat surface on your package. The process requires minimal effort and does not necessitate any specialized equipment or training.Q: What materials and manufacturing processes are used for this impact label?

A: The label is crafted from rigid, transparent plastic using a standard multiple extrusion method, ensuring durability, clear visibility, and consistency in performance.Q: How can my business benefit from using the 75G Impact Label?

A: Utilizing this label adds a layer of security to your shipments by deterring mishandling, providing visible evidence of impact, and supporting comprehensive inspection protocols, ultimately reducing losses and enhancing customer trust.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

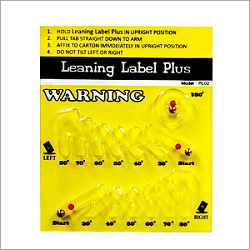

Other Products in 'Leaning Label (Tilt Indicator)' category

We export to Thailand, Taiwan, Singapore, Australia, USA, Russia, Italy and Bangladesh.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese