Impact Tube

3 USD ($)/Piece

Product Details:

- Processing Type Standard

- Condition New

- Click to View more

X

Impact Tube Price And Quantity

- 3 USD ($)/Piece

- 100-500 Piece

Impact Tube Product Specifications

- Standard

- New

Impact Tube Trade Information

- Keelung

- 500000 Piece Per Month

- 1 Week

- Please Contact us for more details.

- SGS

Product Description

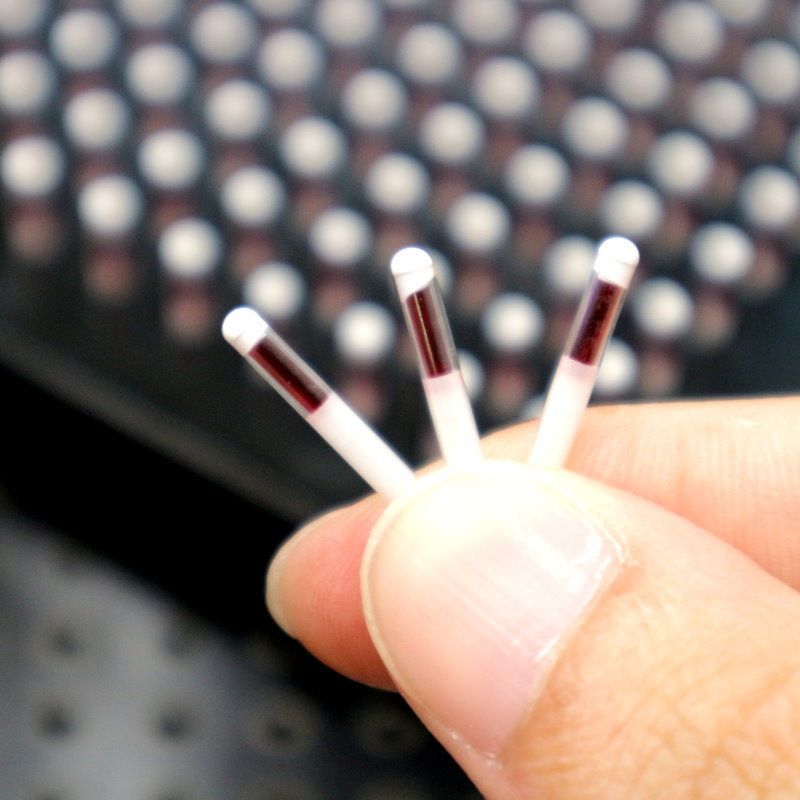

An impact tube indicator is a tiny tube that is primarily placed within the product to monitor impacts and shocks while it is being transported. By directly integrating impact-sensing technologies into customers' products, it gives them a competitive advantage. Because impact tubes are mechanical and don't require a power source, you don't have to be concerned about using more energy. It only has to be mounted into the product to be operational.

It resolves warranty-related problems and provides evidence for you to form early conclusions. Applications for Impact Tube Indicator include computers, cameras, displays, semiconductors, communication equipment, medical supplies, military and aviation equipment, and many more. The red colours start to flow and show up on the indicator pane when damage gets to the product's critical point.

Benefits

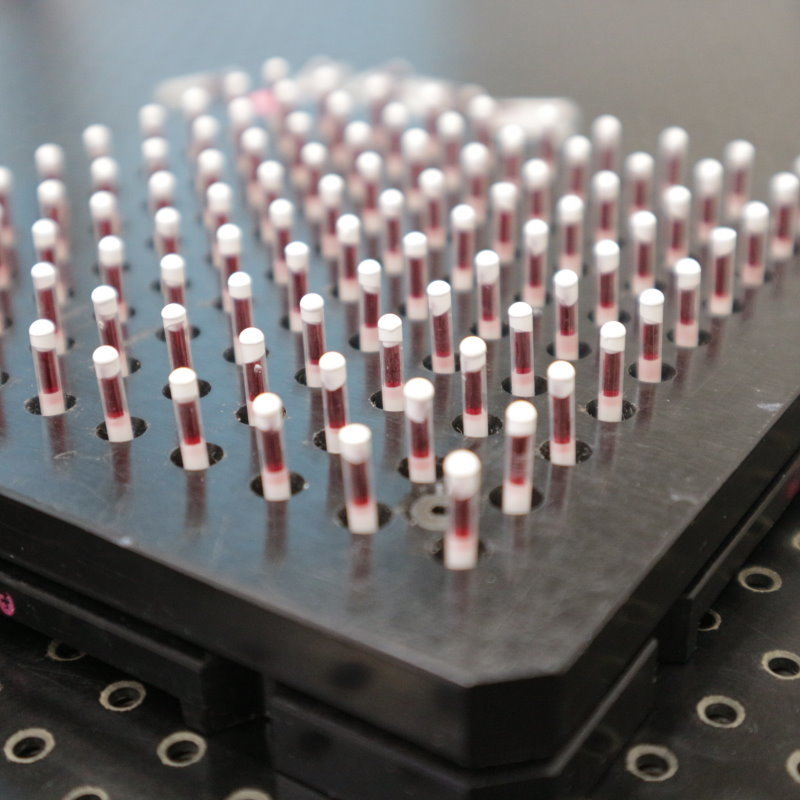

The world's smallest and lightest shock sensor, Impact Tube works similarly to Impact Label. Because impact tubes are small, they can be glued inside of items or products to track their journey from the manufacturer to the terminal. It provides a suitable indication for the goods' warranty service.

Use:

If there is not enough sticky surface, Impact Tube can be put inside the product.

It resolves warranty-related problems and provides evidence for you to form early conclusions. Applications for Impact Tube Indicator include computers, cameras, displays, semiconductors, communication equipment, medical supplies, military and aviation equipment, and many more. The red colours start to flow and show up on the indicator pane when damage gets to the product's critical point.

Benefits

- smallest impact indicator for logistics

- Inform the delivery man of the collision.

- Cut down on shipping damage

- Improve the company's reputation

- Make clear who is accountable for product damage.

- Lower return loss via increasing expenditure

The world's smallest and lightest shock sensor, Impact Tube works similarly to Impact Label. Because impact tubes are small, they can be glued inside of items or products to track their journey from the manufacturer to the terminal. It provides a suitable indication for the goods' warranty service.

Use:

If there is not enough sticky surface, Impact Tube can be put inside the product.

- Computers, Displays, and Different Instruments

- Photographic apparatus, cameras, photocopying apparatus, DV, and communication apparatus

- Medical equipment and supplies

- Aviation equipment and military equipment

Specification:

| Product name | Impact Tube |

| Dimension | 10G~ 37G : 3.4mm x 19mm |

| Operating temperature | -25oC to 80oC (-13oF to 176oF) |

| Sensitivity | 10G , 15G , 25G , 37G , 50G , 75G , 100G |

| Tolerance | + 15% |

| Reaction time | 0.5 - 50 ms |

| Installation | Back adhesive |

| Shelf life | Two years |

| Packing | 10G ~ 37G : 250 pcs/box |

Versatile Customization

Our Impact Tubes can be manufactured to any size, color, and specific requirement you may have. Whether you need a transparent, white, or red tubeor even a fully customized solutionwe can accommodate your request. This flexibility allows us to serve a wide range of sectors, from industrial manufacturing to consumer goods.

Advanced Manufacturing Process

Using multiple extrusion technology and standard processing methods, we ensure each Impact Tube meets stringent quality standards. This approach delivers enhanced rigidity, exceptional transparency, and the durability required for both standard and demanding applications.

FAQs of Impact Tube:

Q: How are Impact Tubes typically used?

A: Impact Tubes are suitable for various applications, including protective packaging, structural components, and transportation of materials or fluids. Their rigid structure and customizable features make them ideal for both commercial and industrial purposes.Q: What customization options are available for Impact Tubes?

A: Customers can select from a range of sizes, colors (transparent, white, red, or custom shades), and other specifications according to their needs. We work closely with buyers to ensure the final product matches their requirements precisely.Q: When should I choose a rigid, transparent Impact Tube?

A: Selecting a rigid, transparent Impact Tube is ideal when you require both strong structural support and clear visibility of the tubes contents, such as in display packaging, protective casings, or applications where monitoring internal materials is essential.Q: Where are Impact Tubes manufactured and distributed from?

A: All Impact Tubes are produced and supplied from our facilities in Taiwan, allowing us to efficiently serve clients both locally and internationally as a distributor, exporter, manufacturer, service provider, supplier, and trader.Q: What is the process involved in producing Impact Tubes?

A: Our Impact Tubes are manufactured through a standard, multiple extrusion process, ensuring consistent wall thickness, hardness, and transparency across all units. Quality control is maintained at each stage to guarantee a reliable product.Q: What benefits does using Impact Tubes provide?

A: The key advantages include durability, ease of use, customizable features to suit unique demands, and excellent clarity or color matching. These benefits help improve operational efficiency and product presentation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

We export to Thailand, Taiwan, Singapore, Australia, USA, Russia, Italy and Bangladesh.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese