100G Impact Label

Product Details:

- Processing Type Standard

- Condition New

- Click to View more

100G Impact Label Price And Quantity

- 4 USD ($)/Piece

- 100-500 Piece

100G Impact Label Product Specifications

- New

- Standard

100G Impact Label Trade Information

- Keelung

- 500000 Piece Per Month

- 1 Week

- Yes

- Free samples are available

- Please Contact us for More Details.

- All India

- SGS

Product Description

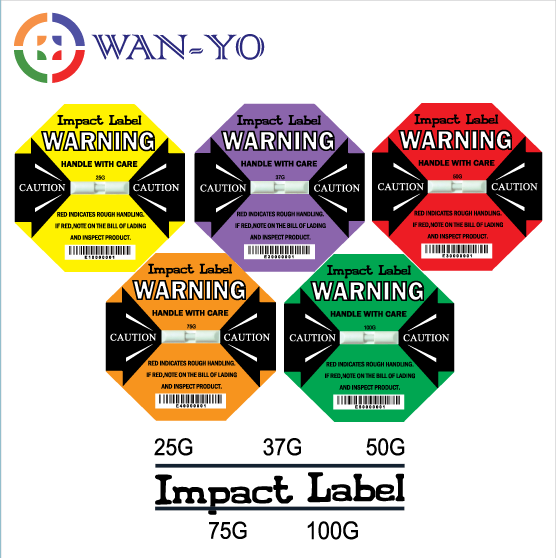

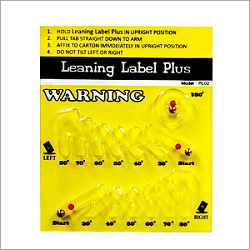

The purpose of the 100G Impact Label is to identify shocks that occur during transit. It is fastened to the exterior of the box to detect vibrations, impacts, and product falls. This indicator window changes from red to white and cannot be reset if it crosses the 100 G threshold. Wafers, motherboards, connectors, and other devices are among the items that use this 100G Impact Label. Its strong adhesiveness enables it to remain on the surface for longer.

Advantages:

VISUAL RISK & ALERT MANGERS

From the warehouse to the destination, the Shock and Impact Monitor monitors the handlers as if you were in charge.

LOGISTICS & HANDLING PROTECTION

Identify Problem Areas in the Supply Chain, Unquestionable Proof of Inaccurate Freight Claims Processing, or Frequent Inaccurate Processing.

Cost-effective, time-efficient, and labor-saving

Reduce the Direct and Indirect Expense of Damage Caused by Transportation. Boost the product's integrity and improve the company's reputation and accountability chain.

EASY TO USE AND Simplify to inspect

Peel and stick is all that is needed; no electricity is needed. Fast Inspection Prior to Approval.

LOGISTICS ACCOUNTABILITY & TAMPER PROOF

A distinct serial number to manage the product conveniently, confirm authenticity, and make responsibility for damage clear.

OEM SERVICE & ISO 9001:2015 CERTIFICATION

Certified International Quality Assurance Control To Meet Every Customer's Package Needs.

| Product Name | Impact Label |

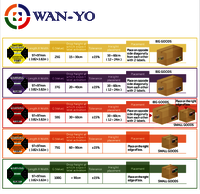

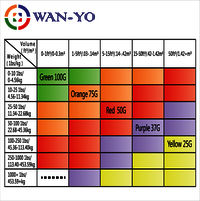

| Models | L-65, L-55, L-47, L-35, L-30 |

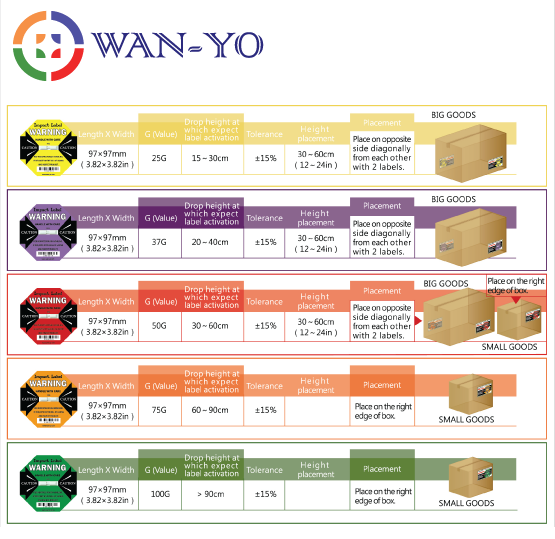

| Dimension | 97mm*97mm (3.82 in 3.82in) |

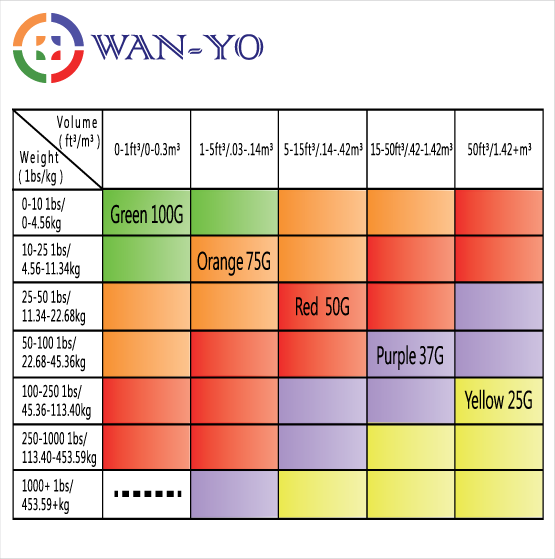

| Sensitivity | 25G, 37G, 50G, 75G, 100G |

| Tolerance | + 15% |

| Reaction Time | 0.5 - 50 ms |

| Operating Temperature | -25 oC to 80oC (-13oF to 176oF) |

| Installation | Back Adhesive |

| Shelf Life | 2 Years |

Ensure Product Integrity During Transit

Our 100G Impact Label acts as a reliable sentinel, indicating if your shipment has experienced potentially damaging shocks. Its innovative design and clear color change help ensure that goods are handled carefully throughout the supply chain, providing peace of mind and reducing the risk of hidden damage.

Customizable and User-Friendly Solutions

Designed to accommodate diverse shipment needs, these labels come in customizable sizes and retain a vibrant green color until triggered. The installation process is straightforward, making them suitable for a wide array of applications, from storage facilities to cross-border shipping.

FAQs of 100G Impact Label:

Q: How does the 100G Impact Label indicate rough handling?

A: The label is equipped with a specialized mechanism that turns red if it experiences an impact exceeding 100G, signaling potential rough handling or shock during transportation.Q: What should I do if the label turns red upon delivery?

A: If the label displays red on receipt, note this occurrence on the bill of lading and immediately inspect the products for any visible or hidden damage before accepting the shipment.Q: Where can I install the 100G Impact Label on my products or packaging?

A: The label is easy to install and can be affixed to any part of your product or its packaging where it can be easily seen and monitored during all stages of handling and transportation.Q: What is the benefit of customizing the size and color of the Impact Label?

A: Customizing the size allows the label to fit various packaging dimensions, while the standard green color makes it easy to spot when undisturbed. Customization ensures optimal visibility and application for your specific shipping requirements.Q: How is the 100G Impact Label manufactured and what material is used?

A: The label is fabricated using multiple extrusion processing techniques from rigid plastic, ensuring durability and precise performance in a range of shipping and storage environments.Q: When should I use the 100G Impact Label in my logistics process?

A: It is recommended to apply the label at the point of packaging prior to shipment, so it can monitor and indicate any shocks experienced throughout the entire logistics chain.Q: Who can benefit from using the 100G Impact Label?

A: Distributors, exporters, manufacturers, service providers, suppliers, and tradersparticularly those dealing in sensitive or high-value goodscan significantly enhance their shipment security and documentation by using this label.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese