37G Impact Label

Product Details:

- Processing Type Standard

- Condition New

- Click to View more

37G Impact Label Price And Quantity

- 100-500 , , Piece

37G Impact Label Product Specifications

- Standard

- New

37G Impact Label Trade Information

- Keelung

- 500000 , , Piece Per Month

- 1 Week

- Yes

- Free samples are available

- Please Contact us for more details.

- All India

- SGS

Product Description

As a customer-focused business, we prioritise quality control throughout the 37G Impact Labels manufacturing process to guarantee optimal performance in all weather scenarios. It accurately detects situations that could lead to product damage during transit, such as falls, impacts, and vibrations. The indication window changes from white to red and cannot be reset after the limit surpasses 37G. Products like LCD substrates, fine arts, precision equipment, communication equipment, etc. are good candidates for the 37G Impact Label.

Advantages:

VISUAL RISK & ALERT MANGERS

From the warehouse to the destination, the Shock and Impact Monitor monitors the handlers as if you were in charge.

LOGISTICS & HANDLING PROTECTION

Identify Problem Areas in the Supply Chain, Unquestionable Proof of Inaccurate Freight Claims Processing, or Frequent Inaccurate Processing.

Cost-effective, time-efficient, and labor-saving

Reduce the Direct and Indirect Expense of Damage Caused by Transportation. Boost the products integrity and improve the companys reputation and accountability chain.

EASY TO USE AND Simplify to inspect

Peel and stick is all that is needed; no electricity is needed. Fast Inspection Prior to Approval.

LOGISTICS ACCOUNTABILITY & TAMPER PROOF

A distinct serial number to manage the product conveniently, confirm authenticity, and make responsibility for damage clear.

OEM SERVICE & ISO 9001:2015 CERTIFICATION

Certified Worldwide Quality Assurance Control To Meet All Customer Package Requirements.

| Product Name | Impact Label |

| Models | L-65, L-55, L-47, L-35, L-30 |

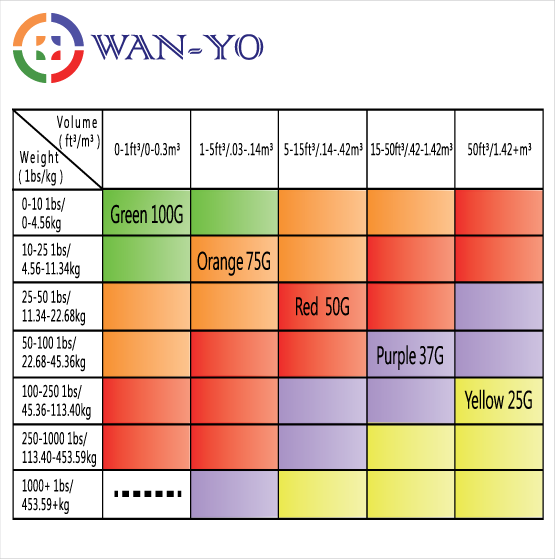

| Dimension | 97mm*97mm (3.82 in 3.82in) |

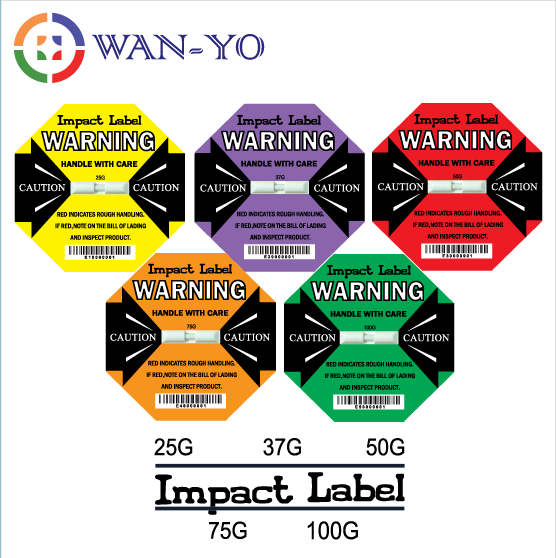

| Sensitivity | 25G, 37G, 50G, 75G, 100G |

| Tolerance | + 15% |

| Reaction Time | 0.5 - 50 ms |

| Operating Temperature | -25oC to 80oC (-13oF to 176oF) |

| Installation | Back Adhesive |

| Shelf Life | 2 Years |

Enhanced Shipment Protection

The 37G Impact Label is specifically engineered to help safeguard shipments against rough handling. Its sensitive indicator instantly reveals shocks by displaying a red signal, empowering recipients and handlers to quickly identify incidents and conduct product inspections. This preemptive measure helps minimize claims and preserve cargo integrity.

Flexible and Customizable to Suit Your Needs

Offered in any size as per your specification, the label seamlessly fits diverse packaging requirements. Its easy-to-install design caters to various operations, whether youre a supplier, trader, or exporter. The purple base and customization options allow adaptation to your logistical workflow and branding.

FAQs of 37G Impact Label:

Q: How does the 37G Impact Label detect rough handling during shipping?

A: The 37G Impact Label responds to shocks by turning red, signaling that the package has been subjected to impact. This visual alert notifies recipients and handlers of potential damage, encouraging further inspection of the contents.Q: What steps should I take if the impact label turns red upon delivery?

A: If the label turns red, you should note it on the bill of lading immediately and thoroughly inspect the products to check for possible damage before accepting the shipment.Q: When is the best time to install the 37G Impact Label on packaging?

A: The label should be installed just before shippingafter packaging is complete but prior to dispatchto ensure reliable monitoring of handling throughout the entire transit process.Q: Where can the 37G Impact Label be applied on a shipment?

A: It is best to place the impact label in a visible location on the package exterior where handlers and recipients can easily see its status upon delivery or inspection.Q: What is the process for customizing the 37G Impact Label to my specific requirements?

A: You can specify the required size and customization options when placing an order. Our team will manufacture labels tailored to your needs using standard multiple extrusion techniques for optimal performance.Q: What are the primary benefits of using the 37G Impact Label in logistics?

A: The label helps detect rough handling instantly, making it easier to identify and address potential damage quickly. This reduces disputes and potential losses, improving overall supply chain transparency and product quality assurance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese